The Advantages of Cold Metal Stamping Parts

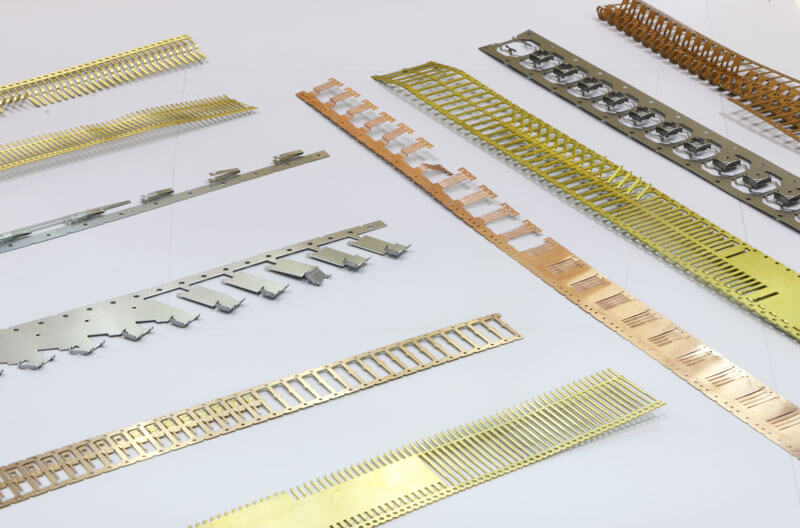

Stamping parts with light weight, thin thickness, good rigidity. The dimension tolerance is guaranteed by the mold, so the quality is stable.It can generally be used without mechanical cutting. Microstructure and mechanical properties of cold stamping parts is better than raw material. The surface is smooth and beautiful. Tolerance grade and surface condition of cold stamping parts is better than hot stamping parts .

Progressive stamping dies with composite modulus or multi station generally are used for batch small parts stamping production.According to modern high-speed multi station press,equip with uncoiling, correction, product collection, transportation , mold base and die exchange device.And control system through computer program. In that way,automatic punching production line with high productivity can be formed. Factory can obtain high precision stamping die with long life,if using new mold material and various surface treatment techniques and improving mold structure.So that, it can improve the quality of stamping parts and reduce the manufacturing cost of metal stamping parts.

Stamping production technology and equipment is developing unceasingly. In addition to stamping parts traditionally used of press and steel die manufacturing. All kinds of special stamping is developing rapidly,such as hydroforming and spinning, superplastic forming, explosive forming, electric water forming, electromagnetic forming technology. Stamping technical level has been raised to a new height. Special metal forming processes are especially suitable for parts production of small batch varieties (or even dozens). As to ordinary stamping process, simple mold, low-melting point alloy mold, die set and flexible manufacturing systems can be used for varieties and small batch stamping mold parts production.

In a word, stamping has much superiority such as high productivity,low processing cost, high material utilization rate, simple operation, easy to implement mechanization and automation. By stamping, welding, adhesive and composite technology, it make the part more structure reasonable.Processing is more convenient. Relatively simple process can be used for producing casting parts with more complex structure.

1 thought on “The Advantages of Cold Metal Stamping Parts”

Comments are closed.