30years

Stamping experience

+/-0.02mm

Dimensional tolerance

<3mm

Material thickness

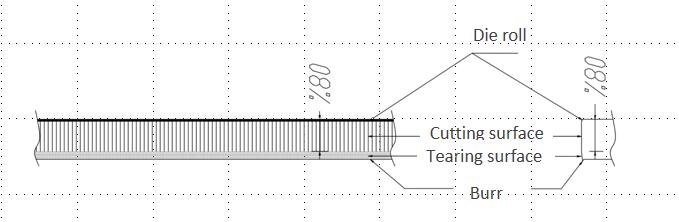

80%

Bright Band

Combine conventional progressive stamping machine and fine blanking tooling to do automate production. High efficiency and stability. With this technology, we’ve mass-produced various products, such as Precision internal structural components for mobiles, Precision components for automotive motors & powertrain systems.

Stamping experience

Dimensional tolerance

Material thickness

Bright Band

A manufacturer in the mobile phone industry wants to make a metal part, which can be used on camera of mobile phone. The customer have requirements on parts dimension tolerance and scratch free.

After checking the customer’s requirements, engineers think fine blanking is better than general blanking and fine blanking can meet the technical requirements.

Fine blanking is a kind of precision machining technology developed on the basis of general blanking. Both of them belong to the separation process, but fine blanking contains the special process parameters of the processing method. The die parts, using fine blanking, also have different quality characteristics. Especially, fine blanking and cold forming (such as bending, drawing, flanging, upsetting-extruding, counterbore, semi-piercing and extrusion, etc.) are combined. Fine blanking parts have been widely used in many fields, such as automobile, motorcycle, consumer electronics, electronics industry, etc. It replaced the parts previously used in general blanking, machining, forging and powder metallurgy processing. So it has technological advantages and economic benefits.

Contact us today to learn how we can deliver solutions for your project.

We provides types of fine blanking stamping parts. Combine 3D modeling and tool simulation with the best tools to provide our customers with tailor-made solutions to meet their complexity, functionality and custom design requirements. With more than 30 years of expertise and experience in die and metal stamping manufacturing, we can achieve better performance than other stamping parts in our industry. Our services include:

Equipped with more than 70 sets of high-speed imported punching machines (30T-160T) and dies processing equipment, which ensures production runs most efficiently and parts are 100% quality assured. We offer a full suite of metal stamping, metal forming, tooling and assembly services.

From sample testing to mass production to delivery, we monitor product quality throughout the process to ensure that each product meets the high standards of our customers.

The company currently has over 300 employees, of which R&D designers and mold technicians account for nearly 50%. The internal mentoring system as the core of the personnel training system, gathered many senior engineers and mold technicians, which has created an excellent team of stamping craftsmen in China.

Hejustamping is a professional manufacturer who is focus on providing electronic components stamping solutions to global customers.

We produce stamping components include wire and cable connectors terminals, battery safety vents, stamped electrical terminals, press-fit terminals/pins, busbars, electrical spring contacts, micro deep drawn parts, electronic shielding components, lead frames, assemblies and more.

Widely used in new energy vehicle wiring harnesses and lithium battery, medical devices, consumables, chip packaging & testing, sensors and other fields.

The daily production capacity reaches millions units, with highly customized production capabilities to meet the special requirements of different customers.

No matter your project is complicated or simple, our experts will provide a solution, you will get an accurate quotation within 12 hours.

© Copyright 2012 - 2026 CNstamping All rights reserved.