Make Progressive Die Toolings in High-Efficient & Stable Production

PROGRESSIVE TOOLINGS

Customized On Demand

Heju stamping provides on-demand customized services for high speed progressive stamping toolings. With more than 30 years of progressive dies stamping manufacturing experience, we can quickly understand your design concept and demand information; We have rich experience in European and American metal stamping dies structure design export and can be made according to your internal die design standards.

Customized Service Content:

- Tooling solution provided according to your production requirements &punching specifications.

- Tooling material & stamping crafts choosed according to your stamping requirements.

- Tooling design conducted according to your standard tooling structure.

With rich experience in metal stamping, Heju can seek tooling technical with you and support to solve all kinds of problems you encountered during production; After receiving the progressive stamping dies, you can set it up on the press and run production immediately. This can support for your standardized stamping production.

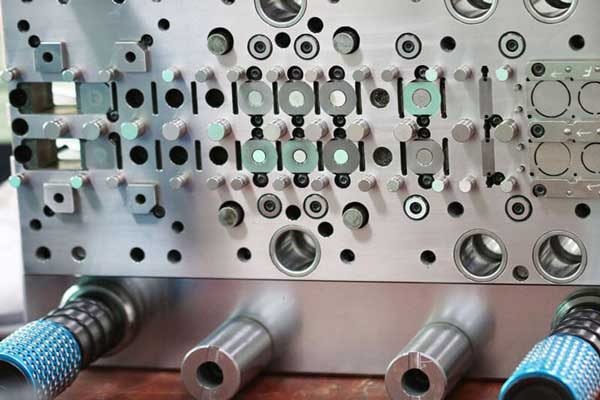

PROGRESSIVE DIES

Stable Stamping Dies Quality

It is an essential point to have a stabled quality progressive tool and dies during stamping. The good stamping dies you use, the higher efficiency you will get. Upon receiving your product design, production demand/ project cycle demands, Heju gonna provide you a suitable stamping dies solution which start from tooling material, fabrication method, standard elements and detecting sensors. Metal Stamping Dies is completely finished in-house from design to fabrication, assembly and trails.

Material of Progressive Stamping Dies

Die sets: S45C/ AL

Die plate: Punch plate, die plate & stripper plate use SKD11 material with cryogenic treatment.

Inserts: Precision Blanking punch & die use carbide material like KD20/VD45

Standard Elements:(MISUMI, MEUSBURGER, AGATON)

Advantages of Progressive Die Toolings:

- Long Life ---- up to 300 million times of shots

- In house tooling service from tooling design to advanced tooling fabrication, assembly and die trails.

- Die plate precision: +/-0.002mm min, inserts precision: +/-0.001mm min

- Long maintenance cycle & Lower repair frequency.

- Max. tooling speed 1500SPM, which can support for your mass production demand during a specified period.

- DFM provided to avoid mass production unstable points or impossible points in advance. Tooling can be kick off for production once received.

Take all your demands into consideration, Heju can provide you a high quality & competitive progressive stamping tools solutions which can support for your long-term & stable mass production to ensure component’s consistence.

PROGRESSIVE DEEP DRAW DIES

Controllable Delivery Time

Heju Stamping now has 60+ technicians, including 10 senior engineers (over 20 years of working experience) who focus on new project’s development. All the process strictly according to ISO9001 & IATF16949 procedures. Stamping tooling’s process can be tracked per internal SOP (formulated & revised according to customer requirements and international practices).

Continuously training procedure conducted to individual workers, from stamping production, tooling maker, maintenance to tooling assembly.

What We do:

- Provide 2D/3D tooling drawings, project engineering management, real-time tooling progress & regular update to ensure on-time delivery.

- Provide trail video/dimension report/online or on-site tooling approval services.

- Provide 2~4 hours trial production service.

What You get:

Tooling schedule Gantt Chart, Latest tooling drawing, Tooling BOM sheet, Operation manual etc.

At the moment, the average delivery time is 45 days once whole stamping tooling design approved by customer. Heju have controllable delivery time management ability and responsible for it. Make all efforts to do what we commit.

PROGRESSIVE METAL STAMPING DIES

Indefinite After-sales Service

It is the beginning once receiving our stamping dies, during tooling lifetime Heju always here for you. Before ensuring you are running stable production, we can also provided the following services:

- Tooling drawing keep the same with tooling itself.

- Each metal stamping tooling made by Heju, were being well kept. No matter how old project you checked, Heju can support to handle as the same.

- Technical service to support for your smoothly production. For any issues you met, let us know and we’ll provide solutions on time.

FAQ

Yes, we can follow your tooling standard. Please share with us your tooling details. That our engineer will design as the same.

Yes, we have our own tool room, there’s oil cutting machine, Sibu, PG, JG. Can fully meet fabrication demand, and process strictly controlled.

Once order confirmed, we will provide strip layout design for initial approve, then move to tooling assembly design, once confirmed then provide whole tooling design for final confirm. Everything ok, then release for fabrication.

In our company we process each tooling as a project, PM control whole things and nominated engineer, tooling maker. They work as the team until tooling transfer.

On other hand, every friday we will update tooling status, each process controlled. And tooling lead time involved with project team members KPI.

Tooling matchs the design. Before transfer, we’ll check the entire tooling and revise the drawing, make sure any modifications during die trails, are been revised.

Tooling well packed by plywood box. And fixed inside. Enclosed our tooling packing SOP for your review, please check.

All the toolings we ship overseas, without any issue.

Yes, we can arrange pilot production based on your reuquest. Pilot production quality control per Heju Stamping process management. Inspection reports can be provided as the same.

Get A Quote For Your Next Projects

If you need a professional progressive stamping die manufacturer to provide you with manufacturing services, whether your project is complex or simple, we can provide you with on-demand customized tooling solutions.

© Copyright 2012 - 2026 CNstamping All rights reserved.