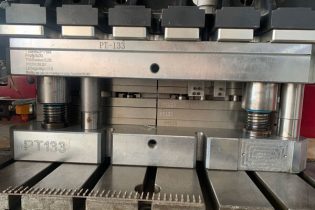

How do Precision Metal Stamping Dies Work?

In the industrial manufacturing sector, stamping dies are the core tools for forming metal parts. They apply external force to metal sheets using a press, causing plastic deformation within the die cavity to ultimately obtain the part shape that meets design requirements. These stamping dies are widely used in industries such as electronics, automobiles, and