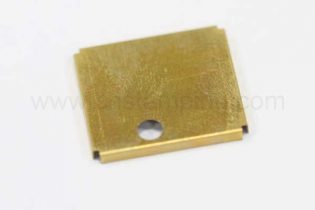

New Energy Vehicle Battery Rupture Discs-Different Explosion Values Analysis

The battery explosion-proof valve of new energy vehicle battery rupture discs is a safety device that controls the pressure inside the battery. When the battery’s internal pressure exceeds a certain value, the explosion-proof valve will explode and release the pressure to prevent the battery from exploding. The burst value of the battery explosion-proof valve refers