Custom Electric Vehicles Prismatic Lithium Battery Safety Vents

Over 70+Models Complete&Free Samples&Fast Delivery

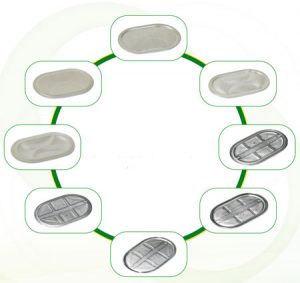

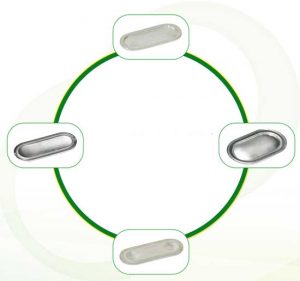

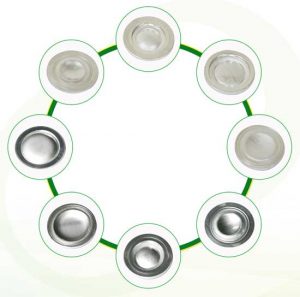

We can custom electric vehicle prismatic battery safety vents in different designs, sizes, shapes, and set pressures.

- Bursting Value is Stable & Safe and Reliable

- Complete models & One-stop Purchasing & Fully Cooperate With New Model's R&D

- Daily Output Reaches One Millions & Continuous Supply & Meet Your Production Capacity Needs

- Strong Technical Support Team & Help You Mass Production

Fully Cooperate with New Models' Design & Manufacturing of Lithium Battery Safety Ventings

Heju Precision has over 30yrs stamping experiences in the manufacturing of micro precision stamping parts. Has entered the field of new energy vehicles lithium batteries in 2016. Focus on the developing and manufacturing of EV prismatic lithium battery safety vents, top sealing plates, aluminum nails, terminals and other small precision metal parts.

The factory has passed three major certifications: ISO9001, ISO14001, and IATF16949. The Punch press machines we used for the massive production of lithium battery safety ventings are mainly imported from Japan and Switzerland, such as YAMADA, Jingli, KYORI, BRUDERER, and other brands.

Why Choose Us for Your EV Lithium Battery Safety Vents Project?

Stable Bursting Value

The tolerance of single blasting value within 0.03MPa, and the CPK value is above 4.0

Most Advanced Imported Film Thickness Tester

Can magnify 1000 times to monitor blasting marks accurately

Perfect Smooth Surface

Good color consistency on the surface

High Scoring Accuracy

The residual thickness of the score is less than 0.005mm

Good Materials

Imported Raw Materials

Our Services

- Save mold fee

- High production efficiency & Controllable cost

- Fast response-3 days delivery at soonesthanical stability

- All Products are traceable, solve all your worries

- Fast proofing, free samples

- Complete specifications, can be equipped with different models

Stamping Capabilities

Precision Metal Stampings

Service

Equipped with more than 70 sets of high-speed imported punching machines (30T-160T) and dies processing equipment, which ensures production runs most efficiently and parts are 100% quality assured. We offer a full suite of metal stamping, metal forming, tooling and assembly services.

From sample testing to mass production to delivery, we monitor product quality throughout the process to ensure that each product meets the high standards of our customers.

The company currently has over 300 employees, of which R&D designers and mold technicians account for nearly 50%. The internal mentoring system as the core of the personnel training system, gathered many senior engineers and mold technicians, which has created an excellent team of stamping craftsmen in China.

Other Stamped Metal Parts

Hejustamping is a professional manufacturer who is focus on providing electronic components stamping solutions to global customers.

We produce stamping components include wire and cable connectors terminals, battery safety vents, stamped electrical terminals, press-fit terminals/pins, busbars, electrical spring contacts, micro deep drawn parts, electronic shielding components, lead frames, assemblies and more.

Widely used in new energy vehicle wiring harnesses and lithium battery, medical devices, consumables, chip packaging & testing, sensors and other fields.

The daily production capacity reaches millions units, with highly customized production capabilities to meet the special requirements of different customers.

Get A Quote For Your Next Projects

No matter your project is complicated or simple, our experts will provide a solution, you will get an accurate quotation within 12 hours.

© Copyright 2012 - 2026 CNstamping All rights reserved.