Are your Gas Sensors Experiencing Frequent Malfunctions? Don’t Let Inferior “Protective Coverings” Compromise your Safety

When the gas leak alarm fails to sound, when gas leak warnings are frequently false alarms, and when a leak accident suddenly occurs in a chemical plant, you might think the problem lies with the sensor’s core chip, but the real issue is with that often-overlooked “protective outer layer.”

Importance of Gas Sensors

As “safety sentinels” guarding the safety of production and daily life, gas sensors have long been integrated into various critical scenarios.

However, this crucial line of defense is often crippled by malfunctions. In the harsh northern winters, sensors in coal mines are prone to freezing and dust blockage due to inadequate sealing of their casings, preventing timely detection of gas leaks and increasing the risk of explosion every second. While in the southern rainy season, if the casings of household gas sensors lack sufficient waterproofing, humid air can easily penetrate, leading to frequent false alarms that are not only annoying but can also cause misjudgment during actual leaks due to component failure. In chemical plants, corrosive gases are “ubiquitous,” and if the sensor casing material lacks sufficient corrosion resistance, the components will quickly be damaged. A leak in such a scenario can lead to millions of dollars in losses due to production shutdowns or even endanger lives.

When choosing sensors, most people focus solely on the performance of the core chip, neglecting the crucial protective “outer layer”—the sensor housing. A low-quality housing is a “hidden killer” for sensors. And the core reason behind the aforementioned series of failures: inadequate sealing allows moisture and corrosive gases to easily penetrate and directly damage the internal precision components. Improper material selection means it cannot withstand high and low temperatures, acids, alkalis, and other complex environmental conditions, leading to cracking and aging in a short period. And unreasonable structural design either blocks the detection holes, affecting monitoring sensitivity, or fails to meet safety standards such as explosion-proof and waterproof requirements, making it unsuitable for complex working conditions. A high-quality sensor, often costing a considerable amount, can be rendered useless by a cheap, inferior housing, resulting in not only wasted costs but also a complete failure of safety measures.

Hejustamping-Your Reliable Sensor Housings Supplier

To address this critical issue and build a robust safety defense from the source, choosing the right sensor housing supplier is crucial.

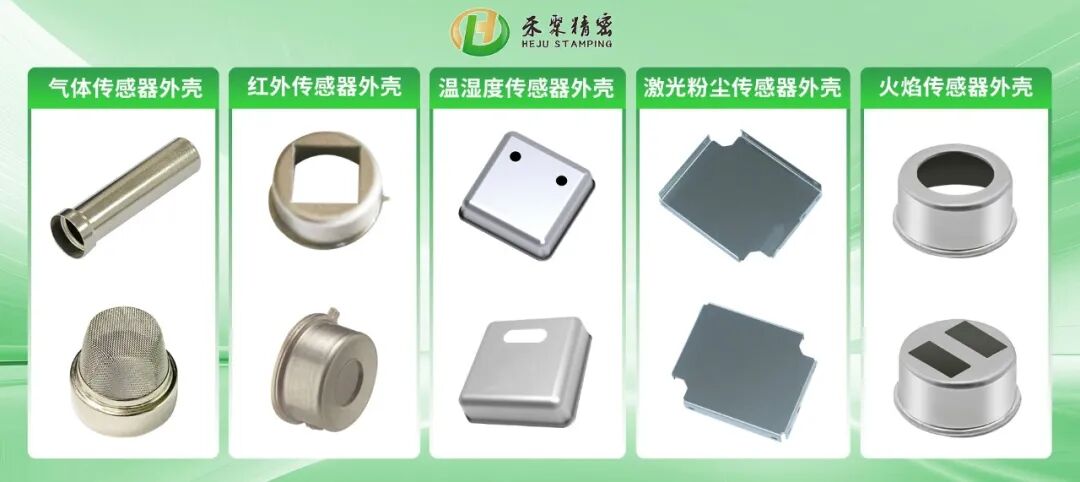

Dongguan Heju Precision Electronics Technology Co., Ltd. specializes in the stamping of sensor housings and has obtained ISO9001 and ISO 14001 international standard certifications. Its product quality meets the stringent requirements of both domestic and international customers. The company focuses on providing metal stamping solutions. From design to production, for various gas sensors, laser dust sensors, temperature sensors, and other types of sensors, effectively addressing a range of safety issues related to sensor housings, such as sealing failures, material incompatibility, and structural deficiencies.