What are the Technical Advantages of Heju’s Precision Deep Drawn Parts?

Precision deep drawn parts are important products in the field of metal forming. They are made by stamping metal sheets into specific shapes. Their core value lies in achieving the production of high-precision, high-strength structural components through standardized processes, meeting functional requirements in complex scenarios.

Technical Principles and Core Processes

The production of precision deep drawn parts relies on stamping dies and metal forming technology. As a key tool, molds plastically deform metal sheets into the desired shape through precisely designed cavities, and their precision directly affects the dimensional stability of the finished product. During processing, the metal sheet undergoes complex deformations such as stretching, bending, and shearing under the pressure of the stamping equipment, ultimately forming a structural component that meets design requirements. The core technology lies in controlling the material flow direction and stress distribution to avoid defects such as cracking and wrinkling, while ensuring surface flatness and edge smoothness.

Material Selection and Surface Treatment

Materials thickness from 0.07mm to 1.0mm, suitable for thin materials as well as normal thickness. Surface treatment employs an electroplating and baking paint process. This involves depositing a metal plating layer on the metal surface and then curing the paint layer at high temperatures, creating a double layer of protection: the plating enhances corrosion resistance, while the paint layer improves wear resistance and aesthetics.

Processing Equipment and Customization Capabilities

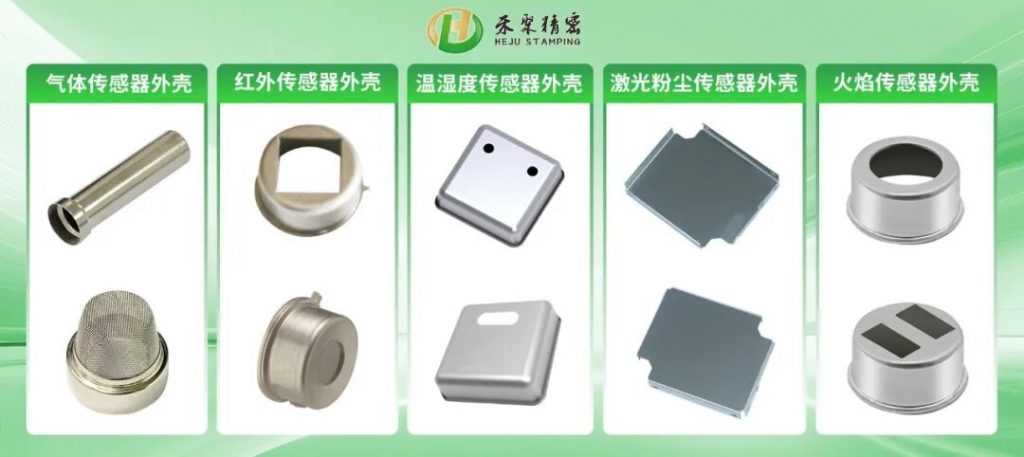

Production relies on advanced stamping equipment, seamless forming up to 50mm depth with ±0.01mm tolerance. Ensuring dimensional consistency across batches. With excellent size adaptation and precision control, the diameter ranges from 150mm to 2.0mm. Smooth, flawless surfaces meet medical and electronic-grade standards. Capable of achieving R/T ratio < 1.0. We’ve mass-produced various high-precision deep drawn components, such as mobilephone linear motor housings, pacemaker housings, Gas sensor housings, etc. Widely used in smartphone vibration motors, cardiac pacemakers, gas sensors, etc.

Quality Control and Service System

The production process adheres to strict quality inspection standards: raw materials undergo spectral analysis to determine purity before warehousing; pressure curves and dimensional deviations are monitored in real-time during stamping; finished products must pass salt spray testing and fatigue testing one million cycles without breakage. Service-wise, we provide full-process support from design consultation to after-sales follow-up. For example, we optimize mold structures based on customer drawings to reduce material waste, or adjust surface treatment parameters for special operating environments to ensure product performance precisely matches actual needs.