Automotive Connectors: Industrial Upgrading “Connector”

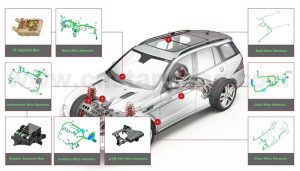

In the complex and delicate mechanical world of automobiles, automotive connectors may seem inconspicuous, but they play a vital role in connection, just like the nerves of the human body. They work silently to ensure that all parts of the automotive electrical system can communicate smoothly, so that the various functions of the car can function normally. Today, let us take a deeper look at automotive connectors, a key role in the automotive industry.

The Role of Automotive Connectors

Automotive connectors essentially play the role of “nerve conduction organs” of automotive electrical systems. These precision components are like transfer stations for electronic signals, establishing energy and information transmission channels between independent electrical circuits. When the current needs to pass through a specific path to achieve a preset function, the connector assumes the key task of circuit connection.

The higher the degree of intelligence of modern cars, the more significant the dependence on connectors. In the field of powertrain, from the ECU control module to the precise ignition of the spark plug, from the millisecond response of the fuel injection system to the energy management of the hybrid system, each key link requires a reliable electrical connection. As for the safety system, the core functions of life, such as ABS anti-lock braking, ESP body stability control, and airbag triggering, all depend on the efficient operation of the connector for signal transmission. In the smart cockpit, from the multi-screen interconnected infotainment system to the seat memory function, from automatic air conditioning to panoramic sunroof control, behind these configurations that enhance the driving experience, there are hundreds of micro connectors working silently.

Systematic Classification and Characteristics of Automotive Connectors

Classification by Connection Technology

1.1 Technical Features of Plug-in Connectors

- The plug-in and socket-to-plug structure supports fast plug-in and unplug operations.

- Core advantages: Assembly efficiency is increased by 30%, and maintenance operation time is shortened by 50%.

- Typical applications: On-board ECUs, sensor modules and other electrical nodes that need to be replaced frequently.

1.2 Technical Features of Crimping Connectors

- The physical bonding of metal conductors is achieved through cold crimping technology.

- Reliability indicators: Contact resistance ≤5mΩ, vibration resistance level up to 10G@2000Hz.

- Applicable scenarios: Vibration-sensitive areas such as engine compartment wiring harnesses and chassis control systems.

1.3 Welding Connectors

- Process requirements: Must meet IPC-A-610 welding standards.

- Mechanical properties: Tensile strength ≥50N, bending resistance >1000 times.

- Application restrictions: Special tools are required for rework, suitable for fixed installation positions such as instrument panel assemblies.

Classification by Functional System

1.1 Power Transmission System

- Environmental requirements: Withstand temperature changes from -40℃ to 150℃, IP6K9K protection level

- Special design: Gold-plated contacts, double locking structure, fuel corrosion-resistant shell

- Typical devices: Engine harness connector, OBD diagnostic interface

1.2 Body Control System

- Protection features: IP67 waterproof design, anti-fretting corrosion treatment

- Connection density: 0.64mm pitch miniaturization design, multi-channel integration

- Application examples: door control module connector, electric seat connector

1.3 Safety Protection System

- Reliability standard: meet ISO 26262 ASIL-D functional safety requirements

- Special certification: airbag connector needs to pass the USCAR-2 impact test

- Technical parameters: signal transmission delay <10ns, failure rate <1ppm

1.4 Intelligent Interactive System

- Transmission performance: support USB3.2/HDMI2.0 protocol, rate up to 20Gbps

- Electromagnetic compatibility: meet CISPR25 Class 5 radiation standard

- Innovative applications: HUD projection connector, smart cockpit fiber optic interface

Development of Automotive Connectors

In terms of technology development trends, connector products are moving towards “miniaturization”, “high-speed mobility” and “intelligence”. Some local manufacturers have exposed the shortcomings of lagging customer service concepts and dull market insight. Compared with the systematic solutions of multinational companies, there is not only a technical gap in engineering capabilities and weak quality control systems, but also a significant gap in customized service response and full life cycle management.

In the context of accelerated iteration of vehicle electronic systems, take the domestic customization capabilities of low-voltage wiring harness terminals as an example. It is now becoming a key breakthrough to break the monopoly of foreign capital. The traditional solution has an insufficient bending radius of the wiring harness due to the large terminal volume, which frequently causes signal attenuation problems. Local suppliers reversely optimize the design based on the spatial layout data of the vehicle manufacturer, and use customized stamping technology to reduce the terminal width while maintaining a current carrying capacity of 15A. Combined with plating technology, the contact resistance is stabilized within 0.5mΩ. This deep customization not only solves the wiring problem of special-shaped vehicle panels, but also reflects the unique advantages of domestic customization.

Hejustamping-Professional Automotive Connectors and Terminals Manufacturer

Dongguan Heju Precision Electronic Technology Co., Ltd. is a manufacturer specializing in the production and design of automotive connectors and terminals. It passed the IATF16949 system certification in 2016. The signal transmission function of the Mini-Fakra terminal and Fakra terminal produced is stable and meets the quality standards of imported brands. The supporting service and quality inspection system are perfect, and more than 50 imported punching machines ensure high-efficiency production of products and strong delivery capabilities. We can actively cooperate with customers’ product needs for customization to achieve domestic substitution!