Comparison and Analysis of Types of Stamping Dies

How to choose the metal stamping dies when a sheet metal stamping company design their own metal products? The most important thing is that they need to consider the stamping die cost is the most cost-effective or not. It mainly depends on the number of parts produced.

Generally speaking, the stamping dies process should be concentrated as much as possible when mass production. That is to use a compound die or a progressive die, which can improve productivity, reduce labor and costs. In the case of small batch production, it is advisable to adopt a single tool and die with simple structure and convenient manufacturing.

But sometimes from the perspectives of convenient operation, safety, feeding and saving site, a compound stamping tooling or a progressive stamping tool also be used even if the batch is not large. For example, If it is inconvenient to take small pieces, from the point of view of feeding convenience and safety, it can be used with material or strip stamping on the progressive tool. If a single tool is used for large stamping parts, it may increase the cost of the tool. In addition, the large stamping part is inconvenient to transfer between processes and also occupies space, so it is also often use a compound tool.

Single Stamping Die vs Progressive Die vs Compound Die

Single Stamping Tool

A single stamping means that only one process of punching or blanking is completed in one punch.

Single Stamping tool according to its guidance can be divided into unguided single stamping tool, guide plate type simple stamping tool and guide column type simple stamping tool.

Progressive Stamping Tool

Progressive Tool and Die refers to finish stamping at different positions of the tool according to a certain sequence of procedures. We can divide the positioning principle into: Guide pin positioning principle and side edge fixed distance principle. Due to the large number of working positions, it is necessary to solve the problem of accurate positioning of strips or strips to ensure the quality of stamping parts in progressive dies.

Compound Stamping Tool

The compound die set refers to the tool that simultaneously completes the upper process of the inner hole and the outer shape at the same position of the stamping tool. Thus, compound dies can be divided into formal compound die and inverted compound die according to the structure. The characteristics of compound die design: the production efficiency is doubled; the quality of stamped metal parts is improved; the precision of stamping tool and die manufacturing is higher.

Summarize

The metal stamping structure of single die is simple, the cost is low, the processing cycle is short, and the adjustment is convenient. Therefore, It is used for stamping components with complex product structure and small production output.

The compound tool design has a compact structure and high precision in one-time forming. Therefore it is suitable for stamping die parts with relatively simple product structure but high precision requirements.

Progressive Die Tooling has complex structure. However, the production efficiency is high as well as high cost, it is suitable for large output of products.

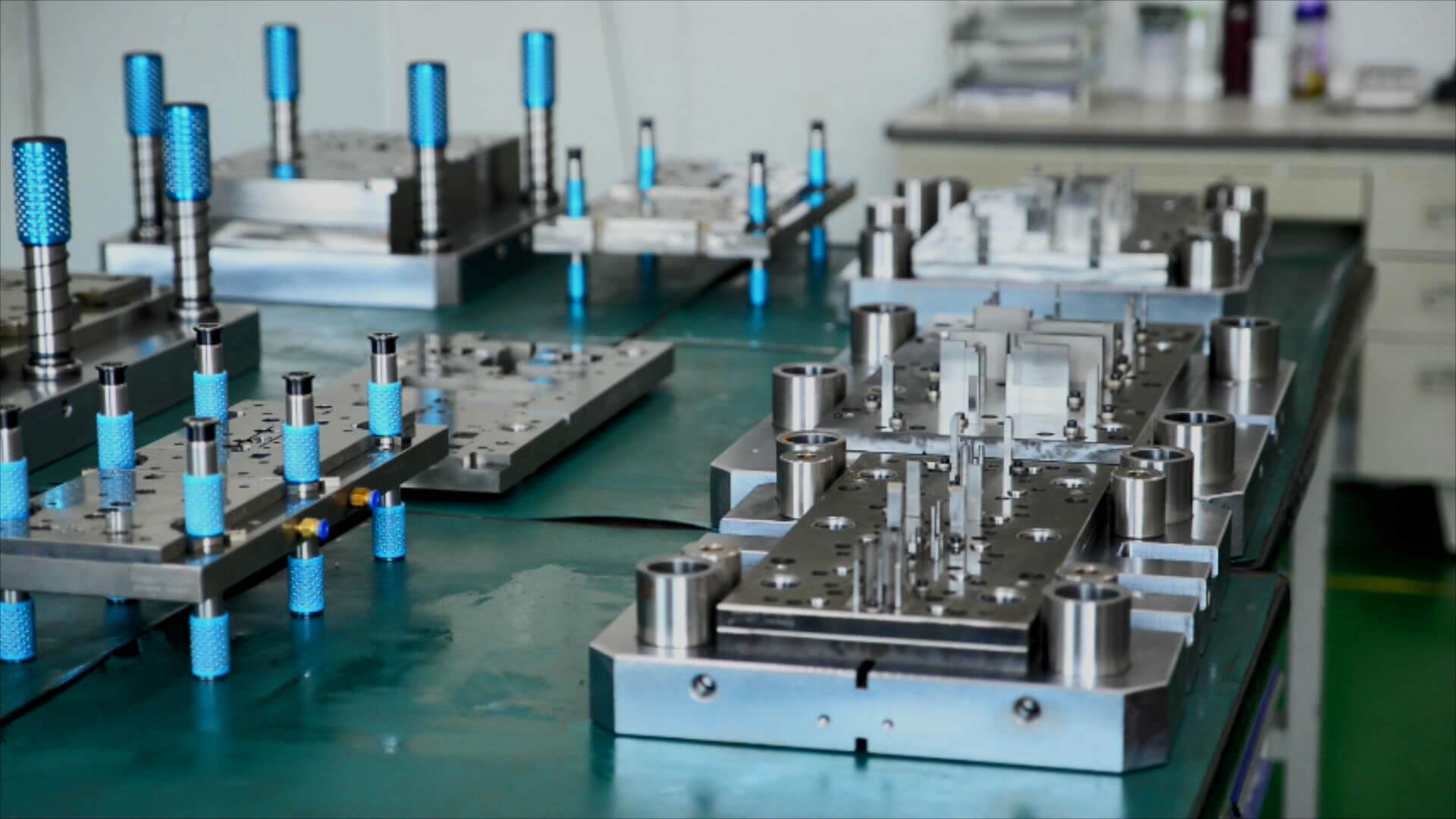

Heju Stamping – A High Precision Metal Stamping Dies Manufacturer

Do you need to evaluate your metal stamping project? Heju stamping is a precision metal stamping manufacturers with more than 30 years of precision stamping experience and specialize in solving complex micro and miniature stamped steel parts, please contact us to solve your metal stamping project.