How to Ensure the Safety of EVs? Lithium-ion Battery Ventings Manufacturer

How to Ensure the Safe Driving for New Energy Vehicles?

New energy vehicles frequently explode because of their batteries. For further energy vehicles, thermal runaway is the most severe and frequent safety accident.

Thermal runaway of automotive batteries results from the heat generation rate being much higher than the heat dissipation rate. A large amount of heat accumulates inside the battery, causing a rapid rise in temperature and causing the separator to shrink and melt. The positive and negative active materials decompose, and other spontaneous exothermic reactions cause batteries to catch fire and explode.

Avoiding thermal runaway is the ultimate goal pursued by countless new energy vehicle battery designers. To achieve this goal, we first need to have a clear and comprehensive understanding of the reaction process of the battery thermal runaway process.

The high temperature in thermal runaway is the first hurdle that hinders us. The high temperature of thousands of degrees will burn out any remaining evidence. Finally, the high speed of thermal runaway is the second hurdle that hinders us. After thermal runaway, the time for the battery to explode is often less than 0.01s, which also makes the safety of the driver unprotected.

Protective Measures

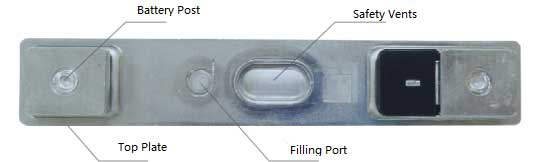

The EV battery safety vents on the power battery top cover provides a strong guarantee for reducing the risk of battery explosion and increasing the window period for personnel rescue.

When the internal pressure of the power battery is too high, the lithium-ion battery ventings will be flushed open, releasing the internal gas, reducing the internal pressure, and preventing the battery body from deflagrating due to excessive pressurization.

At the same time, people usually add reinforcement ribs and burst notches in the design of the ev prismatic battery safety vents. When opening the safety ventings, the battery bursting disc can evenly bear pressure and crack along the notch. The whole body is extended outward to prevent the fragments from damaging other electrical components and causing secondary injuries.

As a company that specializes in the design and development of new energy vehicle battery explosion-proof discs, Heju Precision has developed corresponding explosion-proof disc solutions to address automotive battery safety issues.

More than 40 kinds of EV battery venting standard parts are developed according to the characteristics of various types of car batteries. The basis of all product development is to make cars safer!

Hejustamping-EV Lithium Battery Safety Ventings Manufacturer

Heju’s precision stamping of new car battery explosion-proof discs is visualized from the source materials and has a complete industrial quality inspection process from materials to product delivery. We owned imported equipment from Japan and Switzerland for producing EV lithium-ion battery ventings, such as YAMADA, BRUDERER, KYORI, and other professional brands. The testing equipment is the most advanced in the industry, such as KEYENCE’s high-precision graphic size measuring instrument, non-contact film thickness tester, etc.

There are many specifications and models, and there are standard products without opening a mold. There is always one that can match customer needs. The most important thing is safety! The burst value remains absolutely stable, the single burst value range is within 0.03MPa, and the CPK value can reach above 4.0.

Dongguan Heju Precision Electronic Technology Co., Ltd. has passed the three major certification systems ISO9001, ISO14001, and IATF16949. It has continuously provided high-quality services to the top ten well-known domestic terminal customers, such as Sunwoda, Guoxuan Hi-Tech, Tafel, CATL, etc., with a daily output of one million and continuous supply to meet your production capacity needs.