Micro Deep Drawing Manufacturer-A Core Partner in Miniature Precision Metal Forming

In today’s rapidly advancing precision manufacturing towards miniaturization and integration, micro deep drawing manufacturers play a crucial role. When the core components of a product reach millimeter or even sub-millimeter dimensions, traditional drawing processes face their limits, while micro deep drawing technology becomes the only option for manufacturing miniature sealing shells, precision sleeves, and other parts. A technically strong micro deep drawing manufacturer is not only a supplier but also an engineering partner that assists customers in overcoming design challenges and achieving product miniaturization innovation.

Unique Advantages of Micro Deep Drawing

Compared to conventional drawing, micro drawing is not simply a matter of size reduction. It involves a series of fundamental process changes and extremely high technical barriers:

✦ Dominance of Material Flow and Friction: At the microscale, the grain size effect of materials becomes significant, and traditional plasticity theories partially fail. Simultaneously, the influence of the friction coefficient between the die and the material is drastically amplified, placing nanoscale requirements on die surface finish and lubrication processes.

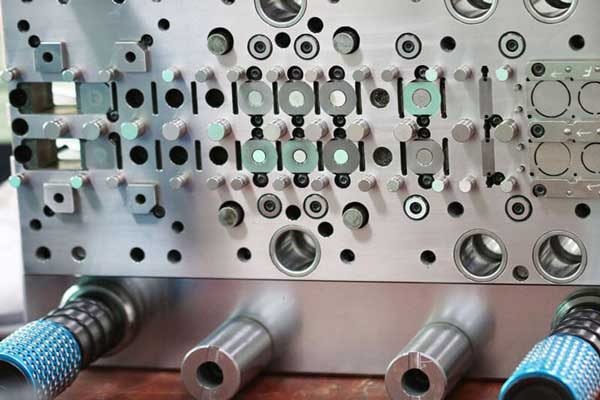

✦Extremely High Precision and Durability of Deep Draw Dies: The machining precision of micro deep drawing dies often needs to be within ±1 micrometer, with extremely small corner radii for the punches and dies. This requires manufacturers to not only possess ultra-precision machining equipment (such as wire EDM and micro-EDM), but also to master special steel treatment and ultra-hard coating (such as DLC) technologies to resist the wear and breakage that are extremely common in micro deep draw mold.

✦Extreme Process Control: Extremely sensitive to fluctuations in blank holder force and stamping speed. It requires a high-rigidity, high-precision miniature punch press and a closed-loop servo control system to achieve precise control of millinewton-level pressure and micron-level stroke, ensuring the stability of each forming process.

Core Application Scenarios of Micro Deep Drawing

Our professional micro deep drawing stamping services are widely used in high-tech fields such as medical devices, microelectronics, communications, and consumer electronics. Examples include sealed titanium alloy shells for implantable neurostimulators, tubular components for minimally invasive surgical instruments, blood glucose monitoring sensor housings, connector housings, MEMS sensor packaging housings, miniature gas spring housings for watches, and TWS earphone handsets.

HejuStamping-Your Reliable Micro Deep Drawing Manufacturer

Production relies on advanced stamping equipment, seamless forming up to 50mm depth with ±0.01mm tolerance. Ensuring dimensional consistency across batches. With excellent size adaptation and precision control, the diameter ranges from 150mm to 2.0mm. Smooth, flawless surfaces meet medical and electronic-grade standards. Capable of achieving R/T ratio < 1.0. We’ve mass-produced various high-precision deep drawn components, such as mobilephone linear motor housings, pacemaker housings, Gas sensor housings, etc. Widely used in smartphone vibration motors, cardiac pacemakers, gas sensors, etc.