Reveal Laser Welding Process of EV Power Battery Safety Ventings

Definition of EV Power Battery

Before understanding the power battery welding, we first need to do a simple understanding of the new energy power battery. The power battery is the “heart” of the new energy vehicle and the main source of its power. The power battery is mainly a ternary material battery and a lithium iron phosphate battery, which has a higher discharge power than the ordinary battery.

As a supporting industry for new energy vehicles, in recent years, the power battery industry has also ushered in growth driven by the new energy automotive industry.

The power battery accounts for 30%-40% of the total cost of new energy vehicles, which is the largest part of the cost of new energy vehicles. And It has a very important impact on the driving range, vehicle life, safety and other key indicators of new energy vehicles. Therefore, improving the performance of power batteries is the key to improving the overall performance of new energy vehicles.

Application of Laser Welding in Power Battery

In the production process of power batteries, from production to battery assembly, welding is a very important manufacturing process. In particular, the power battery structure contains a variety of materials, such as steel, aluminum, copper, nickel and other metals that may be made into electrodes, wires or housings. Therefore, whether it is welding between a material or between a variety of materials, higher requirements are put forward for the welding process.

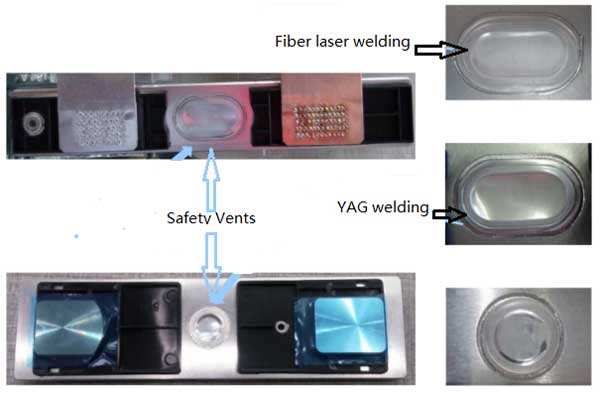

In the entire industry chain of power batteries, laser welding is mainly used in the midstream production of power batteries. It is a high-precision welding method with characteristic of extremely flexible, accurate and efficient. They can meet the performance requirements of the power battery production process. It is the first choice in the power battery manufacturing process, and has become the standard equipment of the power battery production line.

Welding of Power Battery Safety Ventings

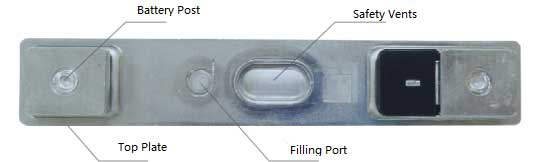

The ev battery ventings of the power battery is the rear process of welding, which is the thin-walled valve body on the battery cover plate. When the internal pressure of the battery exceeds the specified value, the battery venting breaks and deflates first, and then releasing pressure to avoid the battery bursting and causing secondary damage to the car.

The structure of the ev lithium battery ventings is clever, it is usually manufacturerd with two aluminum metal sheets of a certain shapew by laser welding. When the pressure inside the battery rises to a certain value, the aluminum sheet breaks from the designed groove position, which is preventing the battery from further expanding and causing an explosion. Therefore, an adapted explosion-proof sheet is very helpful for laser welding. It requires the weld seal, strictly controls the heat input, and ensures the stability of the damage pressure of the weld, which is too large or too small will have a great impact on the safety of the battery.

About Hejustamping

Dongguan Heju Precision Electronic Technology Co., Ltd. is a professional stamping factory with 30yrs experienced teams. Focus on the R & D and production of new energy power battery safety vents, sealing aluminum nail, power battery cover plate and other battery structural parts of the enterprise. Has passed the ISO9001, ISO14001, IATF16949 three major certification system certification. We have continued to provide quality services to the top ten domestic well-known end customers with a daily output of millions to meet your capacity needs.