Search for Outstanding Precision Metal Stamping Manufacturers

In the manufacturing supply chain, a reliable precision metal stamping manufacturer is often a core factor in determining product performance, cost, and market responsiveness. Whether it’s battery structural components for new energy vehicles, precision metal parts for medical equipment, or miniature motor springs for consumer electronics, the level of precision stamping technology directly determines the reliability and competitiveness of the final product. With so many metal stamping service providers on the market, how do we choose a reliable and professional precision metal stamping manufacturer? In this article, we will focus on the following three aspects to help you better analyze and solve this problem.

Technical Strength of Precision Metal Stamping Manufacturers

An excellent precision stamping parts supplier demonstrates its technical expertise through its ability to control the entire process.

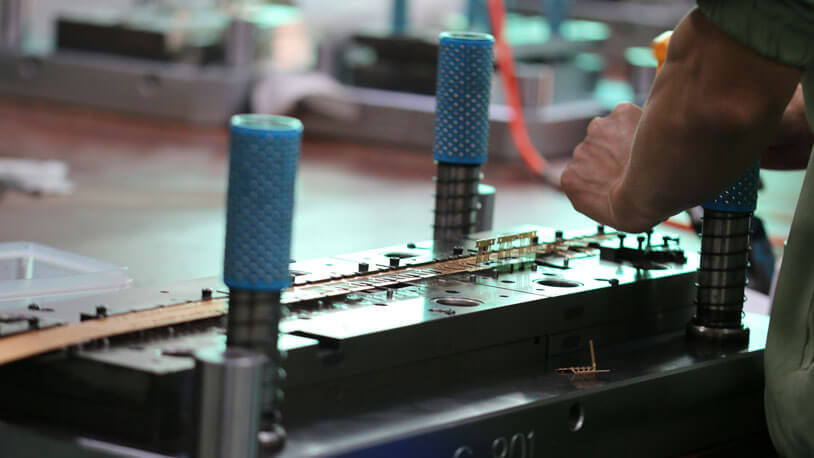

✦ Core Equipment and Mold Capabilities

A truly professional manufacturer will inevitably possess its own mold research and development center. From mold design (CAD), precision machining (wire EDM, mirror surface EDM) to mold testing and maintenance, the ability to control the entire process is the cornerstone of ensuring product accuracy and stable mass production. High-end manufacturers can even perform mold flow analysis based on material characteristics to optimize the process in advance.

✦ Process and Material Knowledge Base

Can they skillfully handle various materials such as stainless steel, copper alloys, aluminum alloys, and high-carbon steel? Do they understand the rebound and hardness change characteristics of different materials during the precision metal stamping process? Professional manufacturers can not only process materials but also act as material and process consultants for their customers, assisting in design optimization (DFM) to reduce costs and improve reliability from the source.

Heju stamping provides on-demand customized services for high-speed progressive die toolings. With more than 30 years of progressive dies stamping manufacturing experience, we can quickly understand your design concept and demand information. We have rich experience in European and American metal stamping dies structure design export and can be made according to your internal die design standards. Factory area 30,000 square meters, fully equipped with tool machinining facility like Wire cutting, EDM, Profile grinding, flat grinding, mirror EDM, etc. Mainly processing the precision stamping die parts and accessories that are used on progressive die, stamping die and plastic mold.

Quality System of Precision Metal Stamping Suppliers

Quality is not inspected into a product, but built into it during manufacturing. Top-tier metal stamping manufacturers deeply integrate their quality system into the entire manufacturing process.

✦ Certification and Standardization

Basic ISO 9001 quality system certification is the entry-level requirement. Automotive metal stamping manufacturers need to have IATF 16949 certification, while manufacturers of precision metal parts for medical devices need to comply with ISO 13485 standards. Behind these certifications lies a complete traceability management system from raw material warehousing to finished product shipment.

✦ Process Control and Inspection

Beyond final inspection, process control (SPC) is crucial. Automated vision measuring instruments (2D and 3D) are installed at critical workstations to monitor dimensional tolerances in real time. AOI (Automated Optical Inspection) is used to detect surface defects and burrs, ensuring that the consistency of mass-produced products reaches a “zero defect” level.

Industry Experience and Solutions of Precision Metal Stamping Companies

The value of experience lies in anticipating and solving problems. A sophisticated precision stamping factory should be a provider of solutions.

✦ Vertical Industry Understanding

Automotive parts stamping manufacturer deeply understand the requirements of standards such as USCAR and VDA regarding terminal conductivity and insertion/extraction force. Medical devices precision metal stamping manufacturers have stringent requirements for material biocompatibility, cleanroom production, and burr-free technology. Choosing a manufacturer with successful case studies in your target industry can significantly reduce communication and trial-and-error costs.

✦ One-Stop Service Capability

Modern manufacturing emphasizes efficiency. Manufacturers that can provide one-stop services, including precision stamping, subsequent electroplating, laser welding, and component assembly. It can not only shorten the supply chain and accelerate delivery cycles but also ensure optimal overall performance of the final components through process integration.

HejuStamping-Your Reliable Micro Precision Metal Stampings Manufacturer

Heju Stamping now has 60+ technicians, including 10 senior engineers (over 20 years of working experience) who focus on new project development. All the process strictly according to ISO9001 & IATF16949 procedures. Products widely used in Products are widely used in automotive electronics, lithium batteries, chip packaging and testing, smart home, consumer electronics, medical device consumables and other fields.

Adopts modern management systems and ERP digital systems to ensure efficient operation.

Equipped with over 70sets high-speed precision stamping presses ranging from 30T to 160T. Featuring brands such as YAMADA, KYORI and BRUDERER, as well as Japanese brand mold processing equipment. From product samples→ mass production → delivery, the product quality is monitored throughout the process to ensure that each product meets the high standards of customers. Contact us for your precision stamping projects.