Stamping Die Components: Types and Function

Usually the stamping die will consist of fixed section and movable sections. The fixed sections will using clamp plate & screw to fasten on the punch press work table, which called lower die. And the movable sections will fixed on the slider of punch press, which called upper die. Then the upper die move up and down with slider to proceed the stamping work.

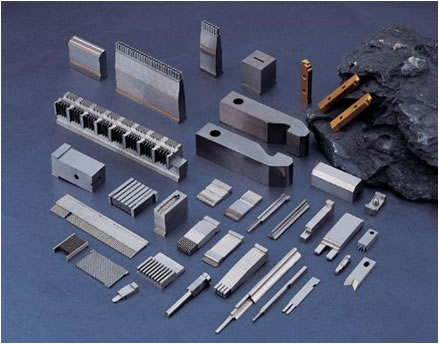

The different components can be divided into 5 types according it’s function:

1. Working components: The working die components are the parts for stamping work, directly make the sheet metal part deformation and separation, then get the stamping work piece. Like punch inserts, die inserts, punch-matrix etc.

2. Pilot components: the function of pilot components is control the raw material feeding direction and feeding pitch, ensure the raw material sheet at the correction location in stamping die. Such as pilot pin, locating pin, guide pin, dowel pin, dowel plate, side clamp plate etc.

3. Components for material press, stripping and lifting: These stamping die parts were ensure the stamping work piece and scraps could be evacuate from tool after each stamping finished, and make the next time production be smooth. For example: Stripper plate, lifting pin, scrap cutting inserts etc.

4. Guide components: These stamping die components are ensure the accurate direction of upper die and lower die during relative movement, make the punch and die inserts have even clearance, then enhance the stamping parts quality.

5. Install and fasten components: These progressive die components function are joint above four kind of stamping die components joint together, to ensure each tool parts’ relative position are accuracy & correct, and make sure the tool can be installation on punch press.

Of course, that’s not say each stamping die should have above 5 type of die components. Once the stamping die will used for prototype or small batch production, to short the validation time and save cost, sometimes could simplify the stamping die structure which only have working components, stripping components and several fasten components. But for high volume mass production tool, except above 5 type of die components, there will additional add automatic feeding and ejection device in stamping die, which can ensure the stamping part quality and increase the production efficiency rate and tooling life time.

Function of Various Stamping Die Components

1. Guide Plate Components

Main function: Guiding the raw material strip at the right location before feeding in tool, make the strip parallel with tool.

2. Punch and Die Components

These components will the main working components in tool, which used for cutting, piercing, forming, bending etc.

For high precision & high volume projects, these inserts will using carbide material which have high hardness, could good ensure the stamping components precision and long life time.

3. Stripper Plate Inserts

These tool parts are put into the stripper plate, used for accuracy guide punch, easy for tool adjustment. There are 3 types of structure: shoulder type, screw fix type, double layer type. The mostly use type is shoulder type.

4. Pilot Pin and Mis-feeder Detection Device

The function of pilot pin is make strip at correction position before tool 1 station working, and mis-feeder is a kind of sensor that can prevent tool shut while miss feeding, which can protect tool away from damage.

5. Main Guide Pillar & Guide Bush, and Sub-guide Pillar & Bush

Above stamping die components all are standard parts which used for tool guide. When stamping die working, usually will use the main guide pillar and post to make a initial guide, then use the sub-guide pillar and post to make precision guiding, which can ensure whole tool sets accuracy.

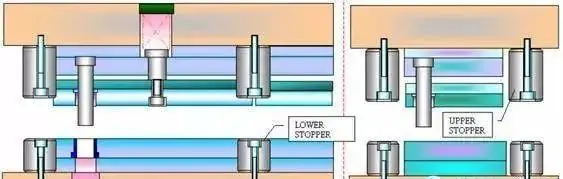

6. Limit Bolt

This stamping die component used for prevent tool damage while the die shut height wrong set, which can protect tool and tool inserts.

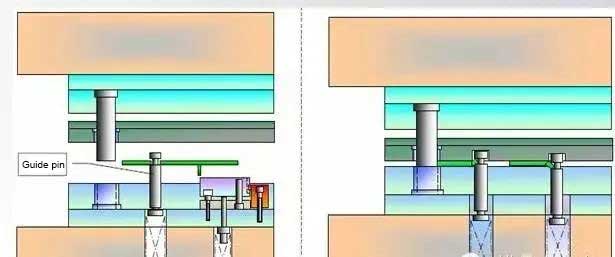

7. Guide Pin

The guide pin is used for material guiding while feeding into mold, also it have the function of material stripping.

8. Clamp Screw

The clamp screw function is to fix the various die component together, provide tight locking force to make the tool be stable while under pressing force.

9. Plug Screw

The plug screw usually together with spring in tool, which can limit the spring compression under the force, also it can adjustment the precompression height of spring

10. Stripper Spring and Stripper Screw

The stripper screw usually use inner thread type, this can not only used for fix stripper plate, also can disassembly the stripper plate. And the stripper spring will mainly provide enough pressing force and stripping force for stripper plate.

More details of stamping die components fabrication method and technology, pls feel free to contact us. Should there any demands of tool inserts fabrication, contact us to get a quote right now!