The Structure and Standard of Automobile Connector Design

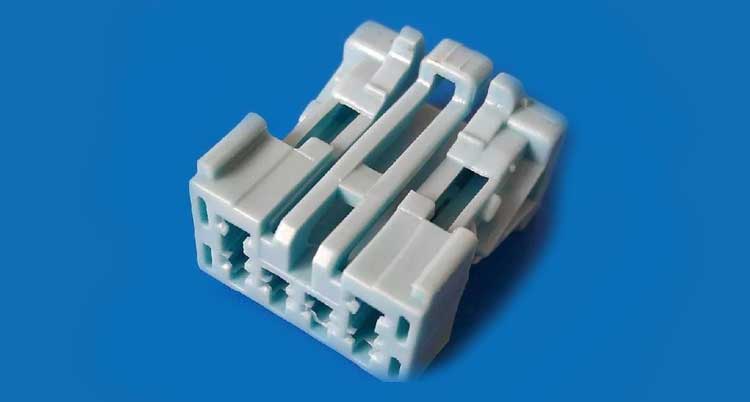

The form and structure of the automobile connector are various. Automobile connectors are primarily made up of contact parts, shell, insulators and accessories. The four basic structures are indispensable.

Contact parts are the most important parts of the auto connector to manage the electrical connection. It is composed of the contact of the positive and negative contact parts.

The shape is cylindrical (round pin), square column (pin) or flat (insert). The positive contacts are made of brass and phosphorous bronze.

Shell is the cover of automobile connector. It is installed inside the insulation of the mounting plate and pin to provide mechanical protection, and provide the plug and socket inserted right alignment, then to fix the connector on the device.

Insulators, also known as automobile connector base or mounting plate, its role is to make contact, in accordance with the need to arrange the location and spacing, and ensure the contact and contact between the parts between the shell and insulation performance. Good insulation resistance, voltage resistance, and process ability are the basic requirements for selecting insulation materials for insulation.

Structure accessories contain retainer ring structure, positioning keys, pins, guide pin, connecting ring, cable clamp, seals, gaskets, etc. Installation accessories contain screw, nut, screw, spring coil, etc. Accessories are standard and interchangeable parts.

With the rapid development of modern automobile industry, automotive connectors have been become smarter, refinement and reliability, the automobile connector appearance, structure design and material are put forward higher requirements.

6 design criteria for automobile connectors:

1. The material for connector contact is stable and reliable.

2. Positive force is stable.

3. The voltage and current are stable.

4. Temperature is required within the specified range, including the surrounding temperature and its own temperature rise.

5. Good robustness.

6. It must be the same connector as the high-speed, long-distance communication computer, which must be able to work reliably in bad conditions.