The Development History of Automotive Wiring Harness Connectors Pins and Terminals

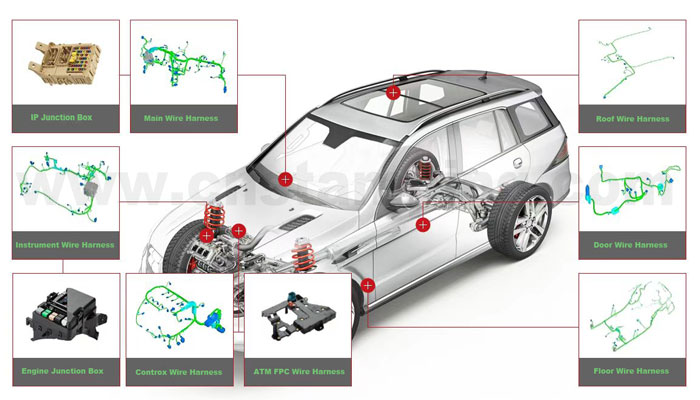

Long time ago, the internal electrical system of a car was relatively simple. But as time went by, it gradually evolved into a complex system that integrates multiple functions. In particular, the rise of chassis wiring harnesses has laid a solid foundation for this change. From the initial wiring harness to today’s complex and sophisticated chassis wiring harnesses, this change not only improves the operating efficiency of the internal electrical system of the car but also paves a solid path for future technological development.

The Birth of Nylon Connectors

When aviation connectors were difficult to popularize due to their large size and high cost, nylon connectors came into being. This plastic multi-pin connector with nylon as the main material is not only cost-effective, but also meets the special needs of the automotive industry.

It uses an injection molding process to form a pair of rectangular docking shells with built-in spade-type terminals, which achieve a stable connection through a contact locking mechanism. In addition, the addition of rubber protective sleeves provides effective protection for the connection points and enhances their reliability in various environments.

Integration of Electronic Technology

From voltage regulators to electronic fuel injection system actuators, from wiper controllers to lighting and wiper control systems, electronic technology is everywhere. This change not only improves the performance and safety of automobiles but also lays a solid foundation for future intelligent development.

Signal processing and sensing functions are also becoming an integral part of this emerging field, and wiring harness layout is gradually becoming more dense to meet the increasingly complex and sophisticated connections of automotive components.

Modern Wiring Harness Design

With the continuous progress of the automotive industry, modern wiring harness design has also shown diversified characteristics. From diverse wire cross-sectional areas, rubber sleeves and connector types to customized designs for specific application scenarios, modern wiring harness design has found a perfect balance between cost-effectiveness and reliability. These innovations not only improve the electrical performance of the car but also provide unlimited possibilities for future technological innovations.

Standardization and Diversification of Connectors

With the rapid development of technology, the complexity of modern electrical systems has reached an unprecedented level. The core of this change lies in the integration of numerous sensors and control electromechanical components, and the key to connecting these complex components, multi-pin electrical connectors, is also constantly evolving towards standardization and diversification.

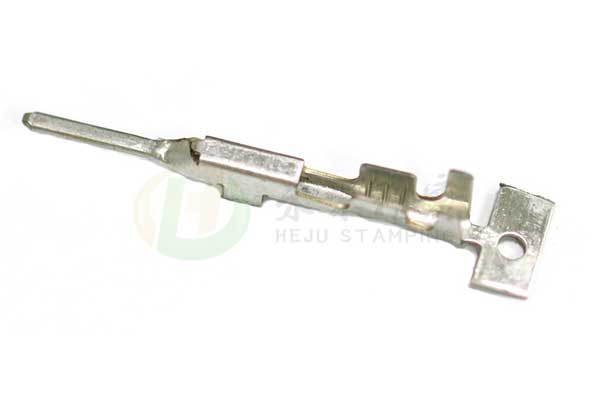

Today’s multi-pin electrical connectors are sophisticated and powerful, supporting up to 100 connection points, and their performance is comparable to aviation connectors. The connector uses precision-made brass or copper and alloy sheets, which are stamped and folded to form cylindrical pins and their matching sockets. The shell design is not limited to rectangular. Complex shapes are also common, and are equipped with a variety of integrated positioning keys to ensure accurate and stable connections.

They use precision-made brass or copper alloys, etc., which are stamped and folded to form cylindrical pins and matching sockets. The shells of these connectors are usually rectangular in design, complex shapes are also common, and they are equipped with a variety of integrated positioning keys.

The main materials of these connectors are various, including PA, PBT, ABS plastic or nylon, etc., which are realized through a precision injection molding process. The internal metal terminals are mostly processed by stamping and lathe. With the rapid rise of the new energy vehicle market, some companies in the low-voltage wiring harness electrical pins/terminals market are unable to meet market demand due to their technical level and lack of innovation, because automotive wiring harness terminals are no longer simple connectors, but higher-level components that integrate devices and control systems.

Hejustamping-Your Reliable Automotive Connector Pins/Terminals Manufacturer

Dongguan Heju Precision Electronic Technology Co., Ltd. is a manufacturer specializing in the production and design of automotive wiring harness connector pins and terminals. It has passed the three major certification systems of ISO9001, ISO14001, and IATF16949. It has many years of experience in connector terminal design and development, and a complete quality inspection system. The thermal and electrical conductivity of the terminals are stable, meeting the quality standards of imported brands. It can actively cooperate with customer product needs for customization and realize domestic substitution!