Top 6 Benefits of Medical Metal Stamping

Over the decades, with the continuous development of technology, more and more industries have been closely related to metal stamping. Manufacturers are no longer limit to the traditional machining technology, but instead choose this fast, efficient and stable production of metal stamping technology to produce. For example, it is widely used in the automotive, industrial, construction, medical, fire industry, etc.

Metal stamping is a manufacturing process that uses a metal stamping die or a series of metal stamping dies to shape the metal sheet into a three-dimensional shape of the workpiece.

This process greatly improves the accuracy and quality of the metal. Since the process is fully automated, this means that manufacturers can perform quick operations without incurring additional labor costs, resulting in significant labor cost savings.

In addition, for projects with a large number of complex parts, metal stamping is the best choice. In this article, we will explore medical metal stamping advantages in more detail, highlighting six key points.

Cost

Cost is a key aspect of manufacturing. Manufacturers often aim to produce high quality products at lower cost. However, compared to the cost of metal stamping and machining, people always consider the latter somewhat expensive, and some complex and sophisticated parts are often difficult to manufacture.

Now stamping breaks this cycle. Metal stamping allows rapid production, thereby reducing the use of machines, the number of workers and labor costs. This significantly reduces production costs.

Accuracy

In the manufacture of medical devices, metal accuracy is critical because of the detailed and complex nature of the process. This can be as low as microns. As imprecise equipment can lead to unpredictable consequences. And even more seriously is directly affect the lives of patients. Therefore, there is no margin for error in the manufacture of medical devices.

Metal stamping operates in a highly automated method which is resulting in ultra-precise parts. This is because of a stamping simulation technique that people use. This simulation technique can identify possible defects before production begins, then it allows designers to refine details and identify gaps in the software itself to make adjustments accordingly. On the other hand, on-chip sensors and cameras help monitor critical dimensions to minimize the margin of error.

Speed

As mentioned earlier, this stamping technology ensures rapid production of complex parts, including medical components. Therefore, manufacturers who previously used original equipment can realize a faster return on investment once they choose metal stamping technology.

Typically, high-speed metal stamping machines produce thousands of strokes per minute. This not only increases production greatly, but also ensures that those companies like pharmaceutical companies can bring new products to market without time delays as soon as they receive them. Metal stamping offers the shortest cycle times per part compared to machining. In addition, die metal stamping takes far less time to set up than any other type of machining.

Flexibility

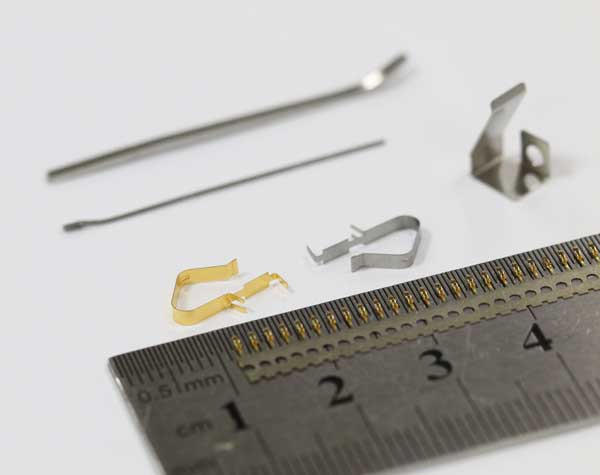

This is probably the most prominent and special benefit of metal stamping. We can turn Lightweight and durable metal back into a variety of tiny and complex precision metal parts. At the same time, there are still high tolerance specifications of the standard. For example, medical parts such as clips, clamps and braces are often very small, the cutting edges of stamped medical components may require a degree of precision.

Cutting-edge micro-stamping equipment means they can be precisely stamped to fit tiny medical deep drawing enclosures – improving designs and expanding the range of options. Likewise, surgical equipment that was previously difficult to machine due to strict tolerances is now available.

Quality

All medical components require a high level of quality to avoid product failures. Especially in medical procedures such as mandibular shell components and highly complex laparoscopic surgeries, the demand for medical stamped parts is highly dependent. Most of the casings of these parts are made of titanium. Titanium is known to resist corrosion and bacterial growth. Titanium is a hard metal, but thanks to this stamping technique, people can now stamp titanium as easily as steel.

In other words, by combining value, accuracy and speed, medical metal stamping makes medical device manufacturing easier. Whether it is surgical instruments, cannula components or implants, components manufactured in this way play a key role in disease treatment.

Production

Stamping equipment is a new technology that is widely used from small batch to mass production. In addition, fast and efficient operations allow medical stamping manufacturers to produce multiple products in a short time. If you need thousands of medical devices, metal stamping is the top priority to achieve this. These are valuable for companies that need large pieces because of their high volume and efficient production.

Why Choose Heju Stamping?

Heju Stamping has over 30 years of experience in precision metal stampings for the medical device industry. Certified by ISO9001 and IATF16949, we have expertise in medical devices and their related requirements. Additionally, we are proficient in the handling of medical grade metals and the precise cleaning and packaging requirements required by our medical customers.

Our senior engineers will design a customized solution based on the customer’s drawings. Using advanced stamping simulation technology to provide information for the design stage. In addition, we also guarantee a fast and efficient precision machining method with almost no waste.

After stamping, we clean and package all stamping components in a safe and clean environment, resulting in a full-service solution.

Do you want to learn more about our medical capabilities? Please contact us today.