Analysis Processing and Difficulties of Precision Metal Stampings

With the continuous advancement of science and technology and the rapid development of industry, precision metal stampings has become an indispensable part of modern manufacturing. In this article, we focus on analyzing the classification and difficult problems of precision metal stamping technology.

Classification of Precision Metal Stamping Processing

The precision metal stampings process can be divided into common processes: punching and trimming, burring, embossing, tooth extraction, bending, stud riveting, etc. The implementation of each product requires more or less relevant technical support to ensure its quality and output. The richer the accumulation of process technology, the shorter the production time of a single product, which indirectly shortens the delivery cycle.

For complex workpieces that require micro-stamping or detailed work, precision metal stamping is often the best solution. Where other metal machining may not be able to meet the precision tolerances required of the workpiece, precision metal stamping can solve challenging problems and machine high-quality parts.

The tolerance of parts produced by precision metal stamping technology can reach ±0.01mm, and the material utilization rate is also high, generally up to 70-85%. It is easy to operate and can produce workpieces in large quantities with good interchangeability.

Difficulties in the Precision Metal Stampings process

Progressive Stamping Dies design and manufacturing

Due to the high requirements for shape and dimensional accuracy of stamping parts, the design of the stamping dies needs to consider factors such as material selection, processing technology requirements, and mold reliability. At the same time, the manufacturing process of the stamping toolings also needs to be strictly controlled to ensure that the processing accuracy and surface finish of the mold can meet the design requirements. Therefore, high speed progressive toolings design and manufacturing are technically difficult and require extensive experience and excellent skills.

Material Selection During the Stamping Process

Different stamping parts have different material requirements. Some require materials with high strength and high toughness, while others require materials with special properties such as wear resistance and corrosion resistance. Therefore, rational selection of materials and ensuring stable quality are very important tasks. In addition, the material’s processing properties also need to be fully considered to avoid problems such as excessive scrap or deformation.

Adjustment of Stamping Processing Parameters

Different stamping parts have different processing requirements, including the setting of parameters such as stamping force, number of strokes, and speed. Reasonable parameter adjustment can ensure the stable quality of stamping parts and improve production efficiency. However, since each stamped part has its unique characteristics and requirements, parameter adjustment and optimization need to be carried out according to the specific situation. That requires engineers to have strong analytical skills and experience accumulation.

Surface Treatment Process after Stamping

After the stamping process is completed, some post-processing processes are often required, such as deburring, polishing, electroplating, etc., to meet the appearance and performance requirements of the product. These post-processing processes require precise control and operation. Otherwise, the quality and service life of the product may be affected. Therefore, the technical level and equipment conditions of the post-processing process are also one of the important factors that determine product quality.

Summarize

Solving these difficulties requires comprehensive consideration of multiple factors and relying on advanced technology and experienced engineers to ensure the improvement of product quality and production efficiency. Only by overcoming these process difficulties can we achieve high-quality, high-efficiency precision metal stamping production.

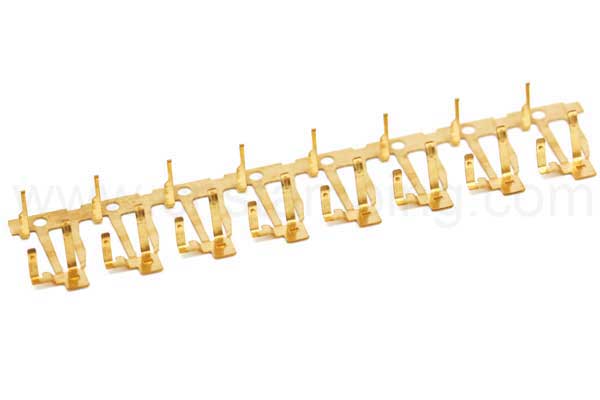

Dongguan Heju Precision Electronic Technology Co., Ltd. was established in 2008. It is a professional ODM/OEM manufacturer specializing in the design and manufacture of precision stamping stamping dies and precision metal stamping parts. Professional production and processing stamped parts including small metal parts, spring contacts, U-shaped terminals, crimp wire terminals, tensile parts and other small precision metal stamping products. Besides, We also provide customers design and drawing services, in order to reduce modifications in product design, shorten the development cycle, and solve worries about the design and processing of molds and parts. Contacts us for your next precision stamping projects.