Difference Between Sheet Metal Stamping & Deep Drawing Stamping (2)

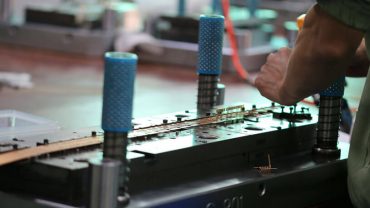

What is Deep Drawing Stamping? Deep drawing stamping is a manufacturing process that uses a mold to stretch a material into its final shape by forcing a sheet of metal into the mold. The main benefit is that it can create complex shapes quickly and efficiently. If you need metal parts with lots of curves