Difference Between Sheet Metal Stamping & Deep Drawing Stamping (1)

Many people wonder about the difference between sheet metal stamping and deep drawing stamping. There are quite a few differences between these two manufacturing techniques.

What is Sheet Metal Stamping Process?

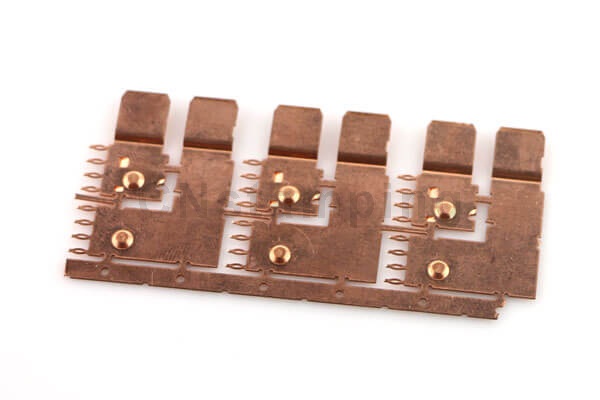

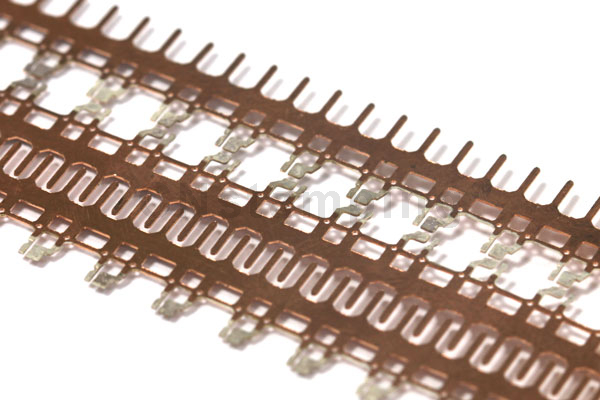

The sheet metal stamping process is transformed by stamping hot or cold rolled steel sheet into the shape required to manufacture your part. This technique allows large numbers of parts to be produced simultaneously, but it can also result in around 15% of the raw material being scrapped. This equipment used with this method requires less space than other methods, so if you have limited space, this type of manufacturing may be best for your business. When choosing sheet metal stamping method, there are three main types of dies used – cutting, punching and bending.

Cutting involves cutting a part from a metal plate. This is done by striking the metal plate with a die, which cuts it into the desired shape. Punched parts will have burrs on the edges, so they need to be filed or machined before use.

Punching is the process of making a hole in a metal plate by placing it between two dies and forcing them together.

Bending is the deformation of metal by using the pressure of a die. This type of stamping is often used to make parts with curves.

Advantages

Low Cost

Sheet metal stamping is a low-cost manufacturing technology. It costs is generally lower than other methods, making it ideal for small businesses with limited budgets. Since this method does not require molds or tools to create the part, it is also considered by many to be less costly. However, the toolless aspect of sheet metal stamping can sometimes make it more expensive because you need to pay someone for the layout and design work instead of using standardized tools.

Mass Production

Metal stamping can produce thousands of identical parts at a time, so this type of manufacturing allows you to efficiently manufacture large numbers of products while maintaining quality standards. This benefit mainly applies to parts that are simple in shape and do not require extensive customization.

Easy-to-use

Shears, punches, and bending dies make up most of the tooling for sheet metal stamping, so this type of fabrication is relatively easy to learn. If you have employees already familiar with basic machine operations, they may know how to punch sheet metal without too much trouble.

Multifunction

Metal stamping is a very versatile manufacturing technique capable of creating parts of various shapes and sizes. This makes it a good choice for businesses that need mass production. In addition, this type of stamping can create both simple and complex parts.

Disadvantages

Scrap Rate

Metal stamping has an inherently high scrap rate. In order to work properly, the stamping die needs a flat, smooth surface of the metal plate. If the sheet is uneven, the effect will be poor and the metal must be scrapped. Because this manufacturing process requires large areas of sheet metal, you run the risk of wasting many small pieces that do not meet quality standards. Obviously, mass production will increases your scrap count.

Not Easy to Customize

Metal stamping works best for straightforward machine parts that require little customization. Simple shapes and curves make manufacturing easy and cheap. However, you may have to pay more when using this technique on custom projects or highly detailed parts, due to design fees and additional labor costs needed to complete the project.

Limited Design and Size Options

Metal stamping is the best option for making simple parts. However, if you need a more complex or detailed part, this may not be the best option for manufacturing. The stamping parts used in sheet metal stamping cannot easily create tight curves or intricate details. So if your part has a complex design, you may have to look for other methods.

Slow Production

Metal stamping is labor-intensive and generally slower than other manufacturing techniques. This can be a significant downside if you need a lot of fast-manufactured products.

See more information on the following articles: Difference Between Sheet Metal Stamping & Deep Drawing Stamping (2).