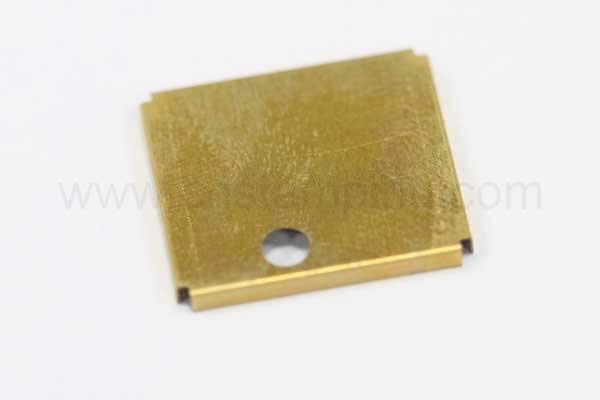

EMI/RFI Shielding Case-Micro Deep Draw Stamping Manufacturing

Everyone knows that the function of the shielding cover is to shield electromagnetic interference (EMI). There are two purposes for the EMI shieldings.

One is to prevent external noise interference. It is generally used on wireless communication boards, especially mobile phone signals.

The other is to avoid the electromagnetic interference generated by itself affecting other electronic equipment (EMC) or causing human burden.

Fixed EMI Shielding

The fixed EMI shielding is directly attached to the PCB by SMT, it is recommended to choose nickel-nickel copper Cu-7521 (R-1/2HorR-OH) as the material. As nickel-nickel copper is better in soldering, heat dissipation, and steam. Except that, The shielding cover can be made of 0.1 or 0.15mm thick material. It is better to choose 0.15mm.

Detachable EMI Shielding

Detachable EMI shielding refer to combine the structure with the LCM or directly buckle the shielding frame with the protrusion on the shielding cover. Generally, it uses materials with a thickness of 0.20mm as much as possible while use materials with a thickness of 0.15mm as less as possible. Tensile shielding brackets must be made of 0.2mm thick material.

Our Deep Draw Metal Stamping Capacity

- Max. Deep Drawing Height: 30mm

- Max. Sheet Thickness Within 1.0mm

- Diameter Ranges From 2.0mm to 50mm

- High Precision: +/-0.01mm

- Can achieve R/T<0.5

Choose us for Your Small &Precision Deep Drawn Parts Projects

Hejustamping is a micro and precision deep draw stamping manufacturer with 30yrs stamping experiences. Focus on manufacturing of small deep drawn components such as sensor shells, VCM motor shield case, pacemaker enclosure, coin vibration motor cases, button cell housing, etc. Products mainly used in the automotive, medical, tele communications, consumer electronics and other industries.

- 30year stamping experiences, focus on customized smal deep drawn stainless steel/aluminium/steel/sheet metal parts & precision deep draw stamping service.

- 36 sets of high-speed punching presses ranging from 30-160T, which can fully meet the short-term/long-term, large-volume, and complex stamping parts requirements.

- Strictly control dimensional tolerances, ensure good consistency of precision and micro deep drawn metal parts, and meet your needs.

Other Deep Drawn Components Cases

© Copyright 2012 - 2023 CNstamping All rights reserved.