Be A Worry-free & Economical Micro Precision Stamping Company for Brand Manufacture

Micro Precision Stamping Company

Heju stamping is a micro precision metal stamping manufacturer with 30yrs stamping experiences. Focus on the manufacturing of complex and high precision stamping metal parts. From prototypes to fabrication, we can provide custom innovative precision metal stamping service for your complex precision metal parts with their mature manufacturer process & advanced industry technology.

We produce stamped components including:

- Automotive connectors terminals;

- Prismatic lithium battery safety vents;

- Stamped electrical contacts&terminals;

- Press-fit terminals/pins;

- Stamped bus bars;

- Spring contacts;

- Micro deep drawn parts;

- Shielding cans;

- Lead frames, etc.

Widely used in new energy vehicle wiring harnesses and lithium battery, medical devices, consumables, chip packaging & testing, sensors and other fields.

Presses from 30 up to 160 tons

SPM Maximum Running Speed

Companies Served

Parts Manufactured

Six Core Technological Advantages

Precision Spring Contact Forming

Good Elasticity&Uniformity

Composite Riveting & Stamping

High Efficiency&Consistancy

Fine Blanking Hybrid Process

High Efficiency&Stability

Micro Hole Piercing

Widely Adapability

Precision Deep Drawing

Excellent Size Adaptation

Cold Forging Integration

High Efficiency&Stability

Micro Miniature Metal Stamping Capabilities

Stamping Process

- Progressive Stamping

- Deep Draw Stamping

- Roll to Roll

- Riveting

- Blanking

- Piercing

- Bending

- Tapping

- Forming

Stamping Capabilities

- Material thickness range 0.04-4.0mm

- Blanking tolerance +/-0.003mm min

Available Material

- Brass

- Beryllium Copper

- Stainless Steel

- Nickel Silver

- Spring Steel

- Aluminum

- Titanium

- Accept Custom

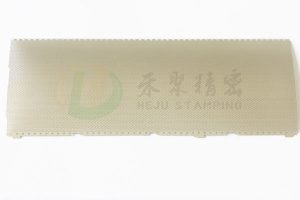

Micro Precision Stamped Parts Cases

Micro Miniature Stamping Solutions

We will select the best metal stamping solutions according to your part capacity, budget and schedule. For expert advice, please contact our engineering teams for answers.

Anually Demand Exceed 100K

Application Scenarios: mass production projects.

Method: progressive tooling.

Advatagement: high production efficiency, good consistency & low cost.

Anually Demand 5K to 100K

Application Scenarios: Trail order to test market, Specific product needs.

Method: Stage tooling.

Advatagement: save tooling cost & development time.

Anually Demand 5K max.

Application Scenarios: product development —- designing/function analysis.

Method: blanking & forming fixture.

Advatagement: save time & development cost.

Why Us for Your High Precision Metal Stamping Projects

Product Experience

Over 30-year-experienced tooling team, keep breaking stamping technical difficulties

Good Consistent

Make sure finished part satisfy all the requirements for the prototypes.

Substitutability

Alternative stamping craft solution, to reduce customer production cost. Eg. Etching

Quality Control

With complete quality traceability system and strictly quality inspection system, Heju can provide high quality & high efficiency product & service for customer.

Short Leadtime

Prototype in 12 days, FOT sample in 20 days for production tooling, mass production: 15-20 days (from raw material purchase to shipment)

Cost

Tooling cost fully refund when reaching contract quantity; cooperate with customer to adjust component design, meet functional requirements and also reduce production cost.

Supply Chain

Build long-term relationship with domestic & oversea raw material suppliers, plating supplier and related fabrication partners.

High Stability

Imported tooling fabrication equipment, regularly tooling maintenance, spare part control

Get A Quote For Your Next Projects

No matter your project is complicated or simple, our metal stamping experts will provide a solution, you will get an accurate quotation within 12 hours.

© Copyright 2012 - 2026 CNstamping All rights reserved.