China Top 100 Micro Precision Metal Stamping Supplier

Established in 2008, Dongguan Heju Precision Electronics Co, Ltd delicated to be your integrated solution&smart manufacturing partner in micro precision metal stamping and high speed progressive stamping dies.

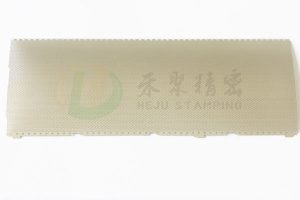

Products are widely used in automotive electronics, lithium batteries, chip packaging and testing, smart home, comsumer electronics, medical device consumables and other fields.

Passed IATF16949, ISO13485, ISO9001 and ISO14001 certificates.

Adopts modern management systems and ERP digital systems to ensure efficient operation.

Six Core Technological Advantages

Precision Spring Contact Forming

Good Elasticity&Uniformity

Composite Riveting & Stamping

High Consistancy

Fine Blanking Hybrid Process

High Efficiency&Stability

Micro Hole Piercing

Widely Adapability

Precision Deep Drawing

Excellent Size Adaptation

Cold Forging Integration

High Efficiency&Stability

Broad Applications

With mature manufacturing processes and industry leading technology, Heju can provide innovative solutions for your most complex precision metal stamping parts.

Such as automotive terminals, press-fit terminals/pins, stamping terminals, spring contacts, EV prismatic battery safety vents, bus bars, sensor housings, which are integral to wire harness connections, battery systems and sensor technologies.

We also produce essential clips for chip packaging and testing, safey clips for the medical industry, including pacemakers, and components for micron motors.

Advanced Workshop Equipment

Equipped with over 70sets high-speed precision stamping presses rangeing from 30T to 160T, featruing brands such as YAMADA, KYORI and BRUDERER, as well as Japanese brand mold processing equipment. From product samples→ mass production → delivery, the product quality is monitored throughout the process to ensure that each product meets the high standards of customers.

Technology-Driven Team

The company currently has over 300 employees, of which R&D technicians account for nearly 50%. Our team comprises 15 veteran engineers with over 15 years of design expertise, 20 engineers with more than 8 years of experience in tooling manufacturing and maintenance, and over 50 skilled technicians with over 5 years of hands-on experience, ensuring every project is executed with unparalleled expertise and efficiency.

Company moved to Daojiao Town with 30,000 factory area.

Heju business school established

Domestic substitution for new energy low-voltage wiring harness terminals, Certified by the ISO13485 system

Customized ERP IT transformation

Prototype team founded Support customer precision NPI sample demands

Entering medical industry to achieve local substitution of medical device components

Huawei chip packaging and testing shrapnel nominated supplier

Developed precision cold forming tooling, supply power battery components for electronical automotive industry

Focus on fine blanking technical, supplying mobilephone precision structure components

Break micron-piercing technical limit, supply components for Dyson

Exporting progressive tool and stamping parts to Ireland and India market, becoming the tier two supplier for Volkswagen electronic parts. In July, Heju moving to a new site at Peihouwei Village, Shatian Town, Dongguan City, the factory area is expanded to 8000 square.

Supplying high performance contacts for Iphone; Pass IATF16949 certificate, within the supply chain of Volkswagen

Developped overseas markets, Products exported to Europe, America

Passed ISO9001 and ISO14001 certificate

Heju stamping established, Specializing in precision stamping parts products for connector

Welcome to Factory Online Visit

We provide factory online visit services, and will communicate in real time through social software. Welcome to make an appointment in advance.

Get A Quote For Your Next Projects

No matter your project is complicated or simple, our metal stamping experts will provide a solution, you will get an accurate quotation within 12 hours.

© Copyright 2012 - 2026 CNstamping All rights reserved.