Considerations for EMI/RFI Shielding Design

Definition of EMI/RFI Shielding

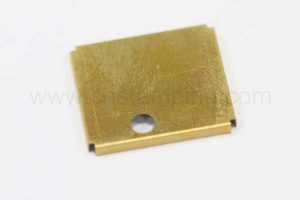

EMI/RFI shielding is the procedure of reducing interference from exterior electromagnetic signals that can interrupt the feature of electronic gadgets. These precise applications rely on EMI/RFI shielding to function properly, from pacemakers to cockpit sensors to microwaves. This shielding has to be the appropriate property, material, and form to efficiently alter the path of unwanted electromagnetic waves and obstruct them from entering or leaving the devices. Engineers and designers create effective EMI/RFI shieldings by selecting materials that attenuate electromagnetic signal strength and positioning them around the sensitive areas of the device.

Purpose of EMI Shielding

Everyone knows that the function of the shielding cover is to shield electromagnetic interference (EMI). There are two purposes for the EMI shieldings. One is to prevent external noise interference. It is generally used on wireless communication boards, especially mobile phone signals. The other is to avoid the electromagnetic interference generated by itself affecting other electronic equipment (EMC) or causing human burden.

Considerations for the Design of EMI/RFI Shielding

Do you know what to consider when designing the EMI/RFI shieldings?

The EMI/RFI shielding can be divided into fixed type and detachable type. Since the fixed shield is directly attached to the PCB by SMT, it is recommended to choose nickel-nickel copper Cu-7521 (R-1/2HorR-OH) as the material. Because nickel-nickel copper is better in soldering, heat dissipation, and steam, except that, The shielding cover can be made of 0.1 or 0.15mm thick material. It is better to choose 0.15mm.

Bending-type EMI/RFI shielding should use materials with a thickness of 0.20mm as much as possible. And materials with a thickness of 0.15mm should be used less. Tensile shielding brackets must be made of 0.2mm thick material.

People should also pay attention to the opening of the shield when designing EMI shielding. On the one hand, it is for the heat dissipation of the internal components during operation. On the other hand, during reflow welding, the temperature difference between the inside and outside of the shield can be reduced to ensure the reliability of welding. Just imagine, if the shielding cover is well sealed and no holes are opened at the high reflow soldering temperature, implosion is likely to occur (the shielding cover bursts and internal components are damaged). There are actual cases of this.

Heju Stamping- Professional EMI/RFI Shielding Stamping Manufacturer

Heju Stamping is an ODM/OEM manufacturer specializing in designing and manufacturing precision metal stamping parts and progressive toolings. Such as automotive terminals, electrical contacts, small deep drawn parts and EMI/RFI Shieldings. Select high-quality raw materials imported from Japan to ensure product safety and long life from the source. Please feel free to contact us if you have EMI/RFI shielding projects.