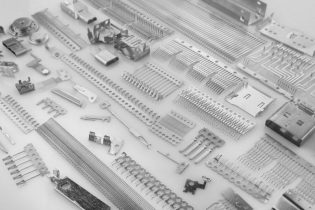

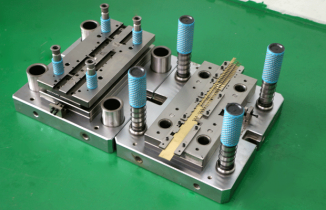

Be closely Linked Together in both Presicion Metal stamping and Automobile Industry

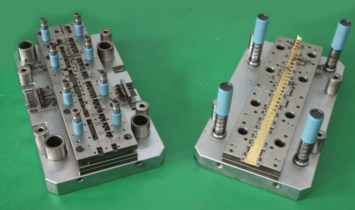

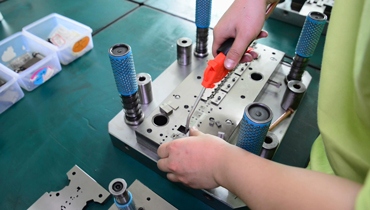

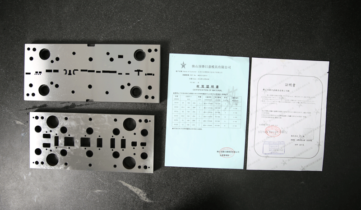

In the great revolution of the diversity and short replacement cycle of automobile toolings, the precision stamping manufactures have been adapted to their own development in the new field. the diversity of toolings can provide more and more types of vehicles by the automobiles enterprises, meanwhile it demands higher stamping process technology, which makes a