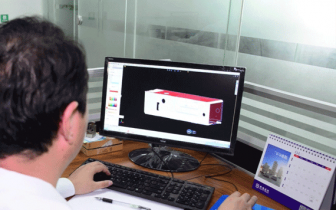

How to Make a Sheet Metal Stamping Die

There are many types of tooling, including single die, compound die and progressive die. To determine tooling form, it must be based on the requirements of the stamping parts, production batch quantity, and tooling fabrication condition. What is Metal Stamping Die? Stamping die is a special process equipment for processing materials (metal or non-metal) into