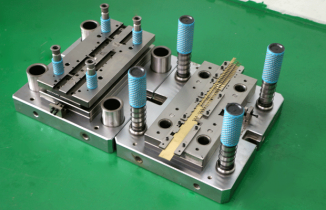

Progressive Die Design

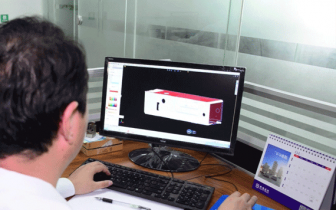

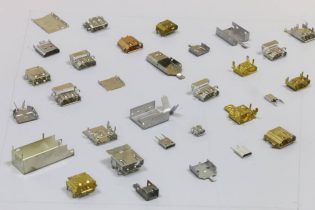

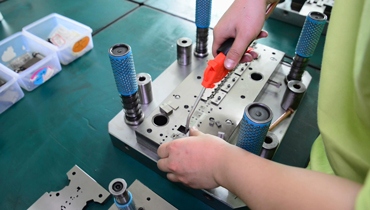

There are many products on the market stamped by progressive die, from the tiny electronic, electrical products to medium and large parts in car and aircraft. And the shapes of the stamping products are variety. All kinds of die processing engineering are differences..The progressive die design general can be divided into five major projects: Understand